This week’s Simple Solutions features

Lathe Machine Automation

Benefits of Lathe Machine Automation

Performance Processing Speed

During the processing of the automatic lathe, the tool holder moves and processes at the same time, so the processing speed of the automatic lathe is 4 to 6 times faster than that of the CNC lathe.

Lower Processing Costs

The cost of an automatic lathe tending solutions lower than that of CNC lathe itself, and its processing speed is faster than manual tending, so its processing cost is lower than that of CNC lathe.

Rule of Thumb

if the batch size is big enough to run unmanned for one hour, it is already profitable to use a robot.

Featured partners – Lathe Machine Automation Solutions.

FANUC

Better cycle time through automation~

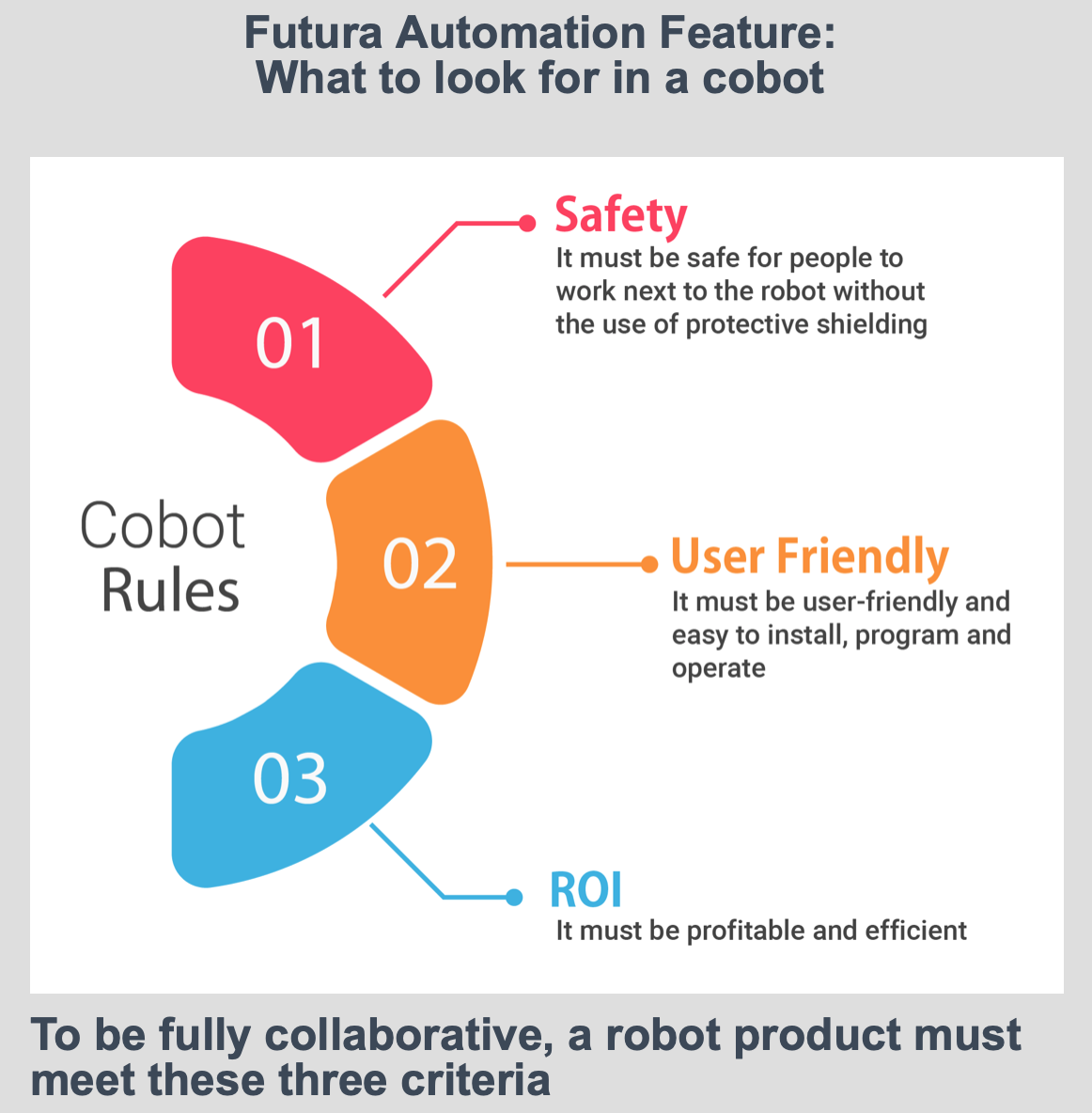

Tending machines is a job that most people are unwilling to do. Good robots or cobots by contrast provide the ability to perform 24/7 of seamless production, multi-tasking between cells, loading and unloading parts and the ability to load and unload several machines if a 7th axis actuator is provided.

ADVANTECH

Start your digital transformation

Our Intelligent CNC Management solution has been developed to bridge the gap from traditional machine management to optimization by facilitating cross-factory machine management in order to improve processing efficiency. It also provides an overview of work order progress, production line availability, and other management services.

OMRON

TM5 Cobots

The OMRON TM5 is a collaborative robot for assembly, packaging, inspection and logistics. Designed to promote a safe and harmonious workplace between humans and machines.

Built-in vision-based robot control enables visual serving, inspection, and measurement

operations.

Recent Comments