In the realm of automation and robotics technology, few companies stand out as prominently as Zimmer Group. With a legacy spanning over three decades, Zimmer Group has established itself as a global leader in the design and manufacturing of automation components and systems. From pneumatic and electric grippers to sophisticated handling damping and linear system solutions systems, Zimmer Group’s innovations solutions have revolutionized industries worldwide. Futura Automation has partnered with Zimmer Group to offer offering a wide range of gripping and clamping solutions in the western United States.

Product Portfolio

Zimmer Group’s product portfolio is a testament to its dedication to excellence and customer satisfaction. This new partnership will enable Futura Automation to offer a wide range of automation components and systems, including:

Grippers: Zimmer Group’s gripper technology represents a pinnacle of innovation and reliability in the field of industrial automation. Zimmer Group’s grippers are engineered to provide precise, efficient and flexible gripping solutions for a wide range of applications in various industries such as aerospace, automotive, electronics, packaging, food and beverage and in pharmaceuticals. At the heart of Zimmer Group’s gripper technology is a focus on precision engineering and high-quality materials. Robotic grippers are designed to withstand the harshest industrial environments, the rigors of industrial use, ensuring long-term reliability and performance. Whether it’s handling delicate electronic components or heavy machinery parts, Zimmer’s grippers deliver exceptional gripping force and accuracy with electronic feedback options.

Tool Changing Systems: For material and part handling, Zimmer Group’s robot and cobot tool changing systems are revolutionizing industrial automation, offering a wide array of advantages and benefits. These systems are designed to enhance efficiency, flexibility, and safety in robotic applications.

One of the key advantages of Zimmer Group’s robot tool changing systems is their ability to improve production efficiency. By enabling robots to quickly and seamlessly change tools, these systems reduce downtime and increase overall productivity.

Another benefit of Zimmer Group’s robot tool changing systems is their versatility. These systems are compatible with a wide range of robots of various payloads and reach along with pneumatic, hydraulic and electrical supplies to the end-effector and verification signals from the tool, allowing for greater flexibility in robotic applications. This versatility enables manufacturers to easily adapt their robotic systems to different tasks and production requirements.

Additionally, Zimmer Group’s robot tool changing systems improve efficiency and improve worker safety by minimizing the need for manual tool changes. This reduces the risk of accidents and injuries, creating a safer working environment for employees.

Machine Tooling Technology: Zimmer Group’s machine tooling technology is a cornerstone of its automation solutions, offering secure and precise clamping and vises for workpieces in a wide range of industrial applications. From machining operations to assembly processes, Zimmer Group’s clamping technology is designed to optimize production processes and ensure high-quality results. One of the key features of Zimmer Group’s clamping technology is its versatility.

The company offers a wide range of clamping solutions, including pneumatic clamps, hydraulic clamps, and electric clamps, allowing customers to choose the right solution for their specific application requirements. Whether it’s holding a workpiece in place during machining or assembling components in a production line, Zimmer Group’s clamping technology can handle the task with ease. Zimmer Group’s clamping technology is also known for its precision and reliability. The company’s clamps are engineered to deliver precise and repeatable clamping force, ensuring consistent performance even in the most demanding applications. This level of precision is essential for industries such as aerospace and automotive, where tight tolerances are critical.

Another key feature of Zimmer Group’s clamping technology is its durability. The company’s clamps are designed to withstand the rigors of industrial use, ensuring long-term reliability and performance. This durability is essential for industries where downtime can be costly, as Zimmer Group’s clamps can help minimize production disruptions and maximize uptime.

Cobot EOAT (end of arm tooling): Zimmer Group’s EOAT offering are essential components that enhance the functionality and performance of industrial cobot. From tool changers and tool stands to force/torque sensors, Zimmer Group’s cobot accessories are designed to improve automation processes and increase efficiency. One of the key features of Zimmer Group’s robot accessories are their versatility. The company offers a wide range of accessories that can be easily integrated into different types of cobot, such as Fanuc CRX, UR, Doosan, Omron, TM Robotics and Productive Robotics, including articulated robots. This versatility allows customers to choose the right accessories for their specific application requirements with minimal installation and programming.

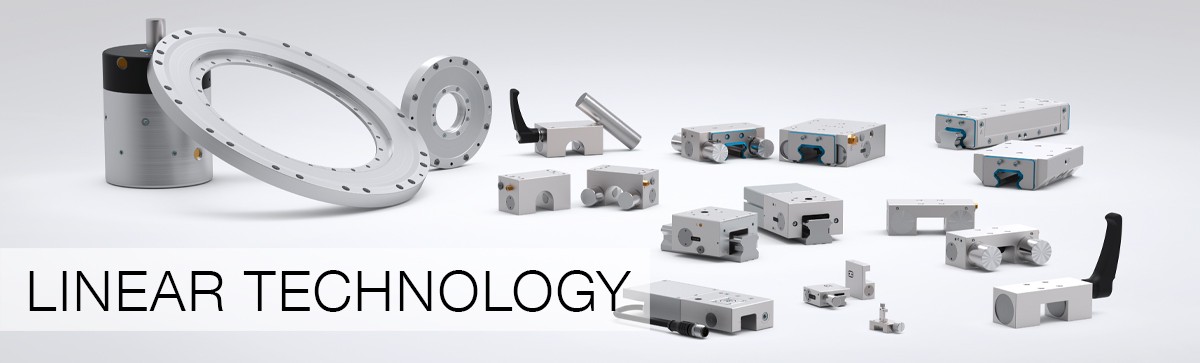

Linear Technology: Zimmer Group’s linear technology is a cornerstone of its automation solutions, offering offers precise and reliable linear motion solutions for a wide range of industrial applications. From linear guides to clamping and braking components, Zimmer Group’s linear technology is designed to optimize production processes and improve overall efficiency. One of the key features of Zimmer Group’s linear technology is its precision. Their clamping and braking elements routinely perform critical positioning, holding and braking tasks. They ensure precision during cutting processes and boost efficiency with short cycle times. These products ensure a secure hold to maximize safety and protect the machines. The company’s linear components are engineered to deliver smooth and accurate linear motion, ensuring consistent performance even in the most demanding applications.

Damping Technology: Zimmer Group’s damping solutions are critical components in industrial automation, ensuring smooth and controlled motion in various applications. These solutions are designed to absorb energy and prevent abrupt movements, enhancing safety and efficiency in automated systems.

With the introduction of the High Energy series, Zimmer Group’s Power Stop industrial shock absorbers use an innovative, organic oil that can be used in the food industry with H1 certification and is even biodegradable. The highest in corrosion protection is achieved thanks to the use of stainless steel for the housing and piston rod. In addition, a new fixed stop with a longer piston rod guide length has been developed to increase the Power Stop’s well-known robustness even more. The product line is completed by an extensive range of accessories.

Cutting-Edge Technology

Zimmer Group’s commitment to innovation is evident in its adoption of cutting-edge technologies such as Industry 4.0 and IoT. By integrating its products with digital interfaces and intelligent control systems, Zimmer Group is helping its customers achieve higher levels of automation and efficiency.

Zimmer Group’s offers most recent innovations is the IO-Link interface technology, which allows for seamless communication between automation components and higher-level control systems. This technology enables real-time monitoring and optimization of production processes, leading to improved productivity and reduced downtime.

Global Presence

Zimmer Group has 125 sales branches and suppliers worldwide enabling Futura Automation to be well-positioned to serve its global customer base quickly with parts readily available from USA headquarters in Hickory, NC. The company’s commitment to customer satisfaction is further demonstrated by its extensive customer support network, which provides expert advice and assistance to customers around the clock.

Zimmer Group’s dedication to innovation, quality and customer satisfaction has made it a pioneer in the field of automation technology. With a diverse product portfolio, cutting-edge technology and global presence, Zimmer Group is poised to continue its legacy of excellence in the years to come. Whether it’s improving efficiency on the factory floor or enhancing precision in manufacturing processes, Zimmer Group’s automation solutions are sure to make a lasting impact on industries worldwide.

We invite you to contact us to help you with your current or upcoming project. tech@futura-automation.com

Published by

President at Futura Automation, LLC

Recent Comments