Futura Automation Futura Automation is proud to present Simple Solutions for Machine Tending that cost less than $10/hr when operated 16 hours per day. Don’t wait to innovate, contact F-A!

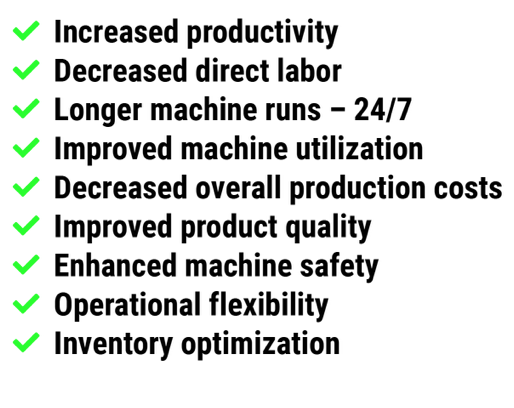

How does Machine Tending make a difference?

Benefits and Overview of Machine Tending:

Machining is the process of material removal of a metal “blank” in order to produce a desired complex shape.Machine tending refers to the automated operation of industrial machine tools in a manufacturing plant, primarily using robot automation systems. While loading and unloading is the primary function of machine tending systems…read more Click to the blog for the full article to explore the benefits of machine tending and learn how to tend machines for < $10 / hour. |

Machine Tending: Solutions and Partners

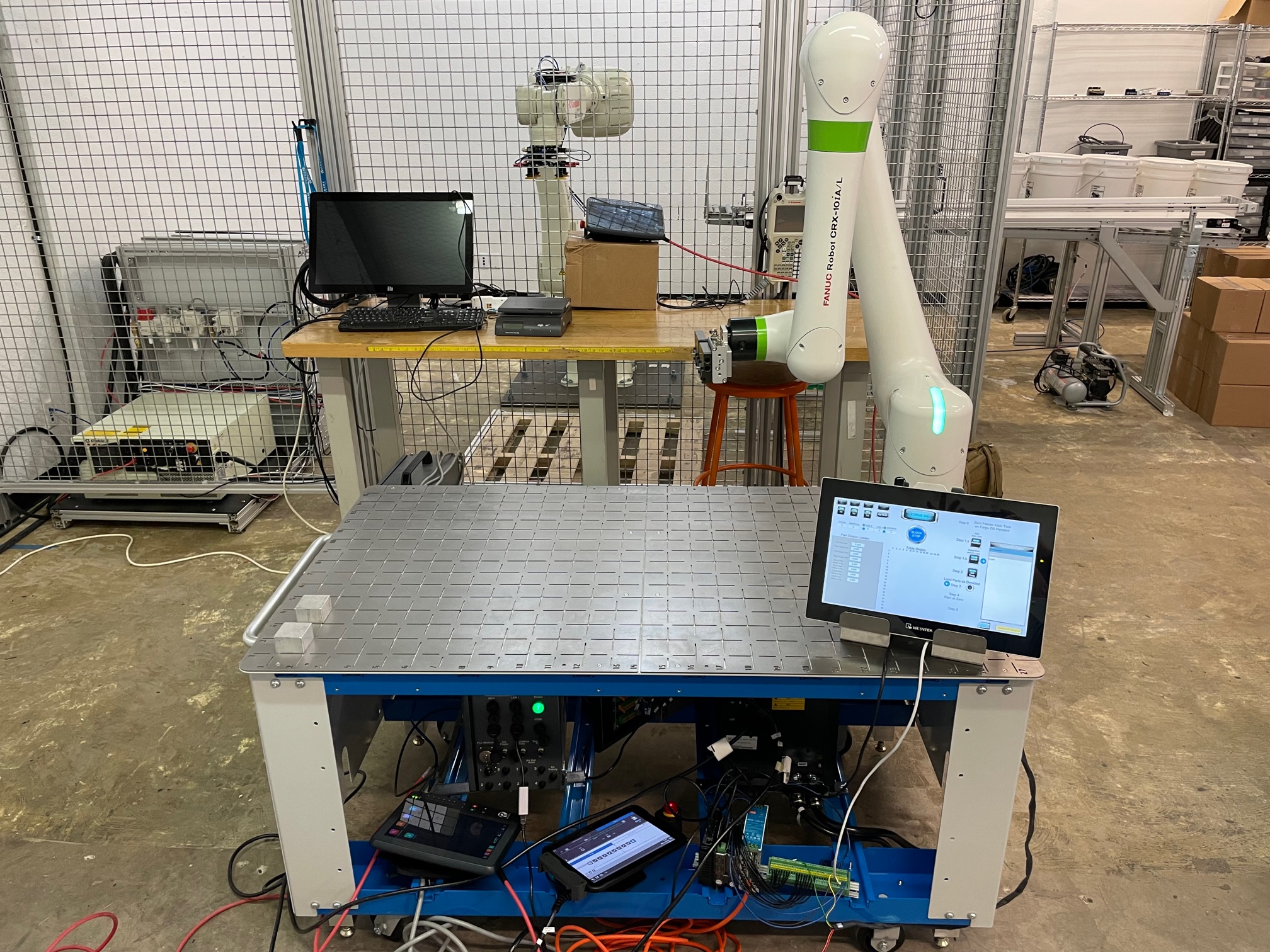

F-A-R Solutions: VM Automation Systems Installed and Running in just one Day

The Vertical Milling Machine Automation System by F-A-R Solutions mitigates operator labor shortages by increasing the productivity of your existing staff. Custom automation solutions built by robot system integrators often leave you dependent on the integrator to add new parts for automation; an expensive and time-consuming proposition. The F-A-R Solution, in collaboration with Ready Robotics, is a standard automation system that requires no robot expertise or robot programming to use. Changing between jobs takes just minutes, maximizing equipment and operator productivity.

OMIL: Mechanical Gripping, Machine Tool Workholding, Vises and Clamping

The company OMIL, Settimo Torinese (Turin-Italy), is specialized in its forty years of activity, in gripping systems and handling of parts for machining. OMiL is among the world leaders in the handling of heads, cylinders and aluminum rings.

The position of strength achieved depends not only from a broad range of solutions but also the technology and reliability of products, such as the gripping and handling in challenging environments ( die casting or hot stamping). All this is possible through the constant search for new materials, processes and solutions.

Weintek: Human-Machine Interfaces with Codesys PLC control and Cloud Data Service

Futura Automation represents Weintek, an amazing set of solutions for human-machine interface (HMI). Ever since Weintek introduced the two 16:9 widescreen full color HMI models in 2009, MT8070iH (7”) and MT8100i (10”), newer models have soon led the market.

Before, most manufacturers focused on small 5.7” greyscale and 10.4” 256 color HMI models. Weintek responded with the most intuitive and feature-rich EasyBuilder screen development software. Within 5 years, Weintek was the best-selling HMI worldwide, and the 7” and 10” 16:9 touchscreen became the standard in the industry field.

Weintek has continued this innovation and Futura is pleased to offer new full featured CODESYS programmable controller solutions embedded in a low cost HMI. We offer a range of compact digital and analog I/O with Canbus, MODBUS TCP, Ethernet IP and EtherCAT interfaces. Let us help you save money while greatly improving quality and performance

Recent Comments