| Presses» | |||||||||||||||||||||||||||||||||||||||||||

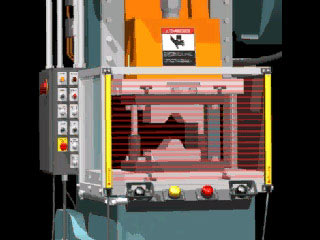

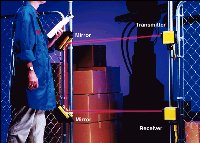

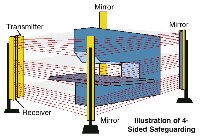

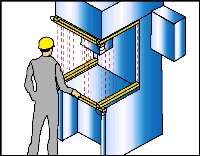

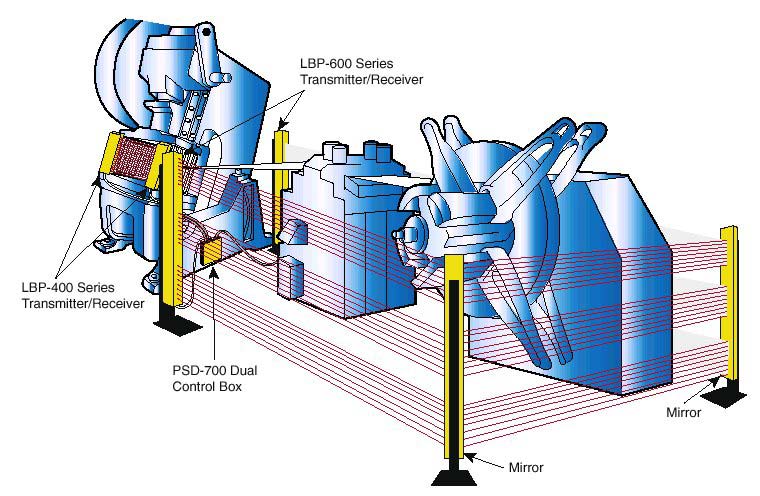

Presence Sensing Devices are one of the most common safeguards for automatic feed part revolution clutch presses. They are designed to automatically stop the machine stroke if the sensing field is interrupted. Proper use of presence sensing devices provides protection not only for operators but also for other employees in the area. They also minimize operator resistance to these types of safety devices due to their nonrestrictive design. Presence sensing devices are commonly referred to as light curtains. There are many requirements that must be met before light curtains can be installed as point-of-operation safeguards.

| |||||||||||||||||||||||||||||||||||||||||||

Recent Comments