Maximize Your Operation

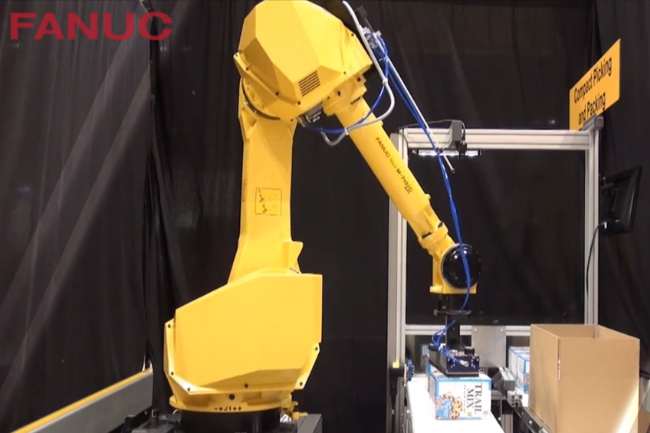

Robots and cobots combined with machine vision and conveyor belt, flexible feeder or bin picking tools allow for automated pick and place systems.

Belt feed systems are ideal for pick and place from one belt to another for bulk packaging typically using a delta or SCARA (4-axis) robot to accomplish picks better than one per second.

For small part flexible feeding, machine vision locates the parts singulated by eccentric motion on a flat surface and a 4 or 6-axis robot to pick and place the part. With bin picking, a 3D vision scan locates parts that are random in orientation in a bin or box allowing a 6-axis robot or cobot to grip a single part and move it to its placement location in a fixture or nest.

Benefits are high cycle rates as low as 2 seconds per cycle, high repeatability, elimination of human contamination and low labor cost.