Direct material laser marking (laser engraving, etching, engraving, annealing etc., ) is a fast and effective way to permanently mark parts and materials. A laser beam interacts with the material to create lines, numbers, a logo or any desired mark for easy tracking, control and tracing. From jewelry, surgical parts and industrial parts, to dog tags, awards and guns, our laser marking systems are used in a number of industries.

With a 20 year history in DPSS laser marking systems including popular fiber laser marking systems in 1064 nm and 532 nm wavelengths, RMI Laser understands the need for high-performance and a low total cost of ownership. Laser marking systems including laser engraving machines are our singular focus, and we know how to provide maximum value. For example:

- All RMI laser marking systems are designed, manufactured and supported in the USA with performance, affordability and longevity in mind.

- RMI’s local (Denver), in-house software development team provides clear and actionable answers and support whenever you need it and our fully-staffed customer service department is ready to assist with anything else you may need.

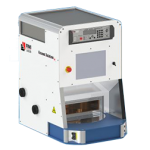

- Futura Automation installation and training are available for every laser system.

- Futura Automation laser safety enclosures (laser workstations) are designed to uphold optimal standards in operational protection.

- RMI’s best-in-class marking laser parts are backed by an exceptional non-prorated warranty good for up to five years

- RMI’s convenient, laser system loaner program helps you remain productive in the event your system needs repair