Keeping your machine tool busy for less

Better cycle times through better automation

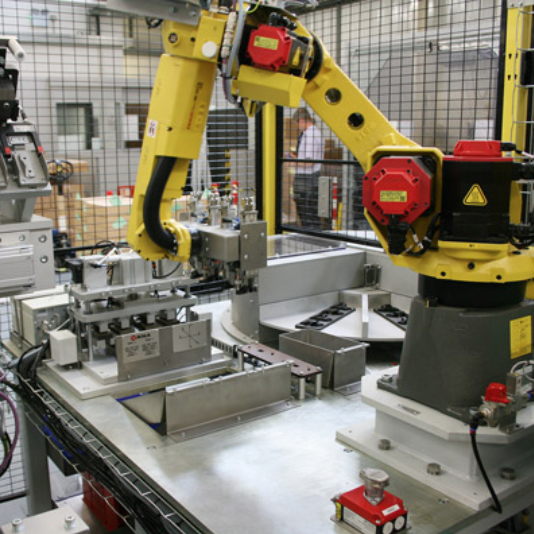

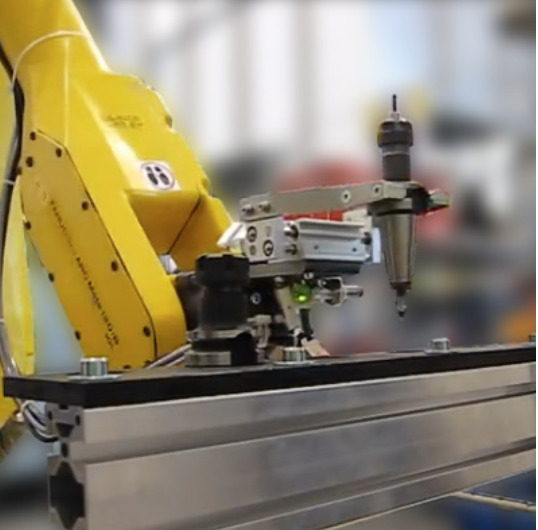

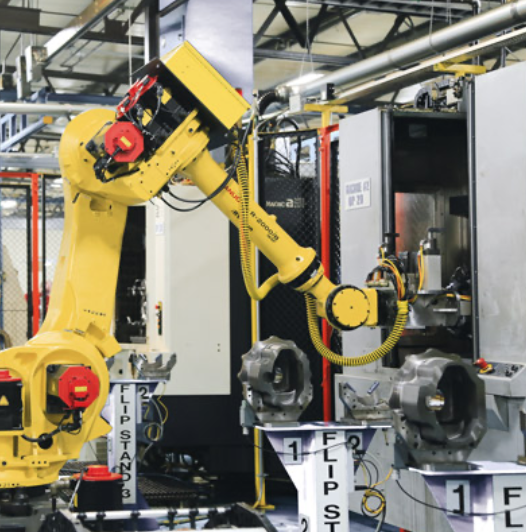

Good machine tending robots bring efficiencies to tasks as varied as sand casting, injection moulding, cutting, machining and small parts assembly. Leading suppliers should have solutions for every conceivable production scenario, from the smallest to the largest and in any cell configuration. They should also offer a comprehensive range of support services, with both local and global support at your fingertips whenever you need it.