Automation has been too difficult for too long.

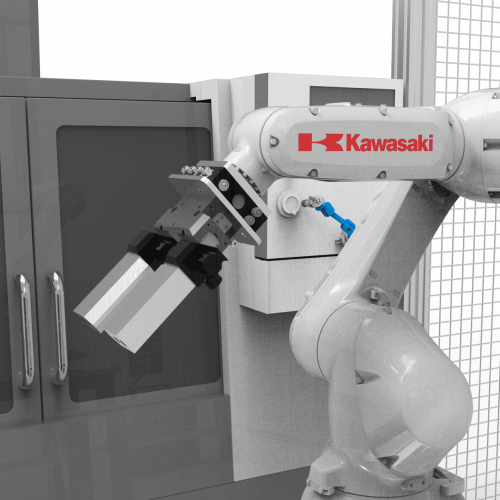

Futura is excited to demonstrate the power of Forge/OS – a brand-agnostic platform that brings world-class useability to industrial robots and automation components. With Forge/OS, heavy payload industrial robots are as user-friendly as collaborative robots.

Forge/OS makes automation more accessible than ever before – enabling anyone on the production floor to run a system, manage changeover, touch up programs, program for new parts, and recover a system.

Multiply the impact of your team with the automation platform that doesn’t require a background in robotics or automation to succeed.

Advanced Robotic Solutions to Optimize Your Operation

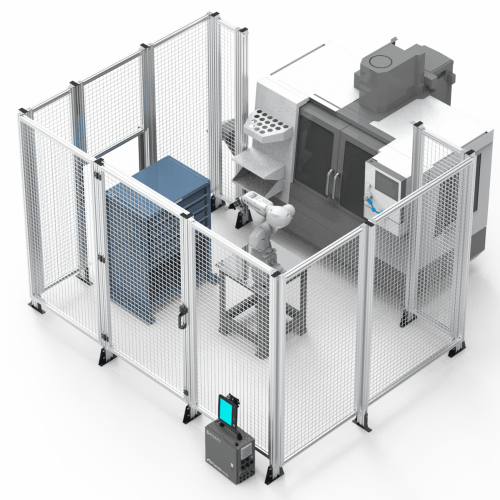

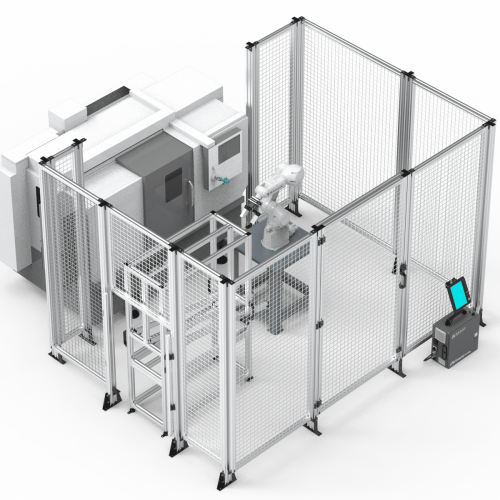

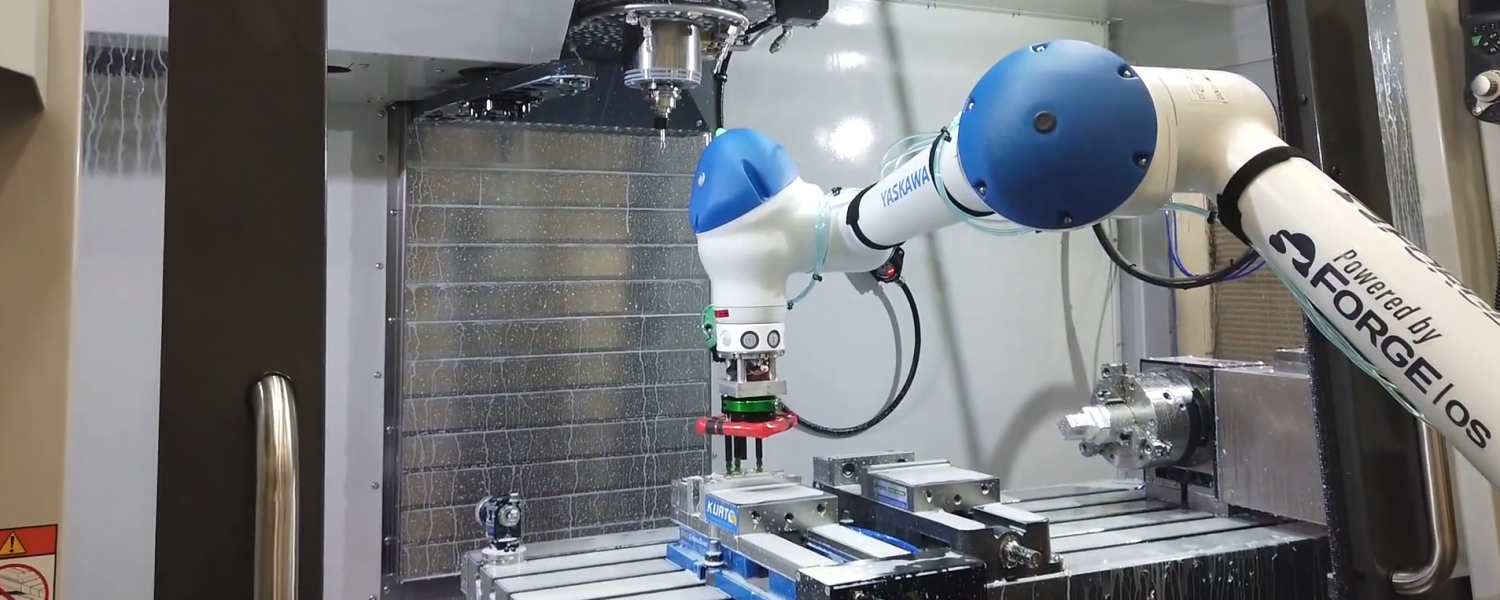

Mill Machine Tending

Easily set up a CNC machine tending cell to automate your milling process. Maximize the investment of your CNC mill by running lights out production with a Fanuc CRX10L cobot, ideal for small parts. Utilizing a cobot can eliminate the requirement for fencing and guarding.

Automate your CNC Mill in days. Automating CNC machine tending with a robotic cell powered by READY’s Forge/OS will make it faster, easier, and more affordable than ever to automate your CNC mill.

With easy-to-use programming software, and all-inclusive automation hardware kits, READY makes it easy for anyone to automate their CNC Mill. From picking parts to machine interaction, Task Canvas touchscreen app brings a new level of simplicity to programming a robot. CNC Mill automation has never been easier.

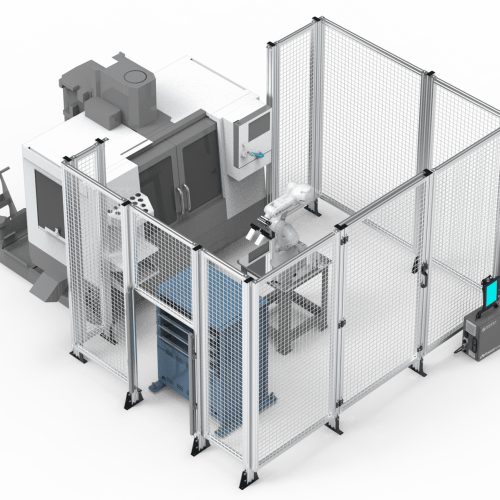

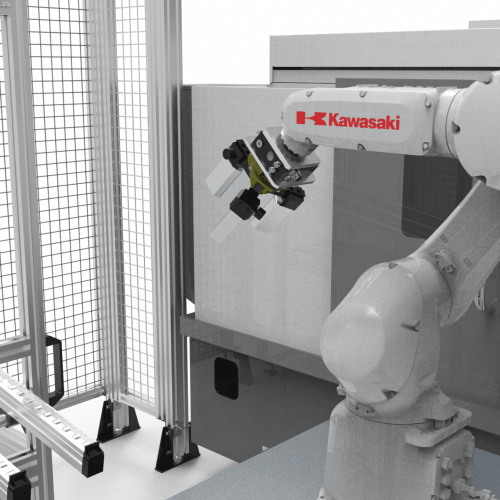

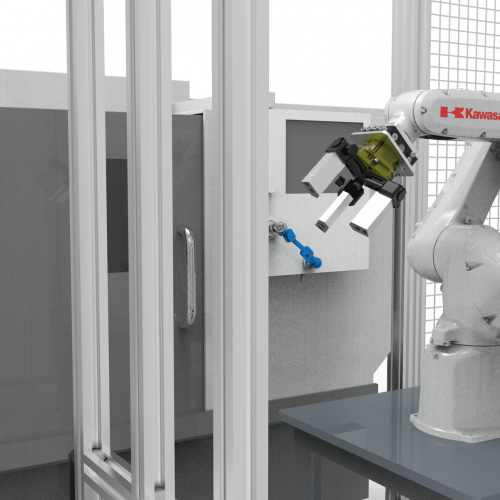

Lathe Machine Tending

Easily set up a CNC lathe tending cell to automate your turning process. Maximize the investment of your CNC lathe by running lights out production with a Fanuc CRX10L cobot, ideal for small parts. Utilizing a cobot can eliminate the requirement for fencing and guarding.

Automate your CNC in days, not weeks or months. An automated CNC machine tending cell powered by READY’s Forge/OS will make it faster, easier, and more affordable than ever to automate your CNC machine.

With easy-to-use programming software, and all-inclusive automation hardware kits, READY makes it easy for ANYONE to automate their CNC. From picking parts to machine interaction, Task Canvas touchscreen app brings a new level of simplicity to programming a robot. CNC machine automation has never been easier. No need to have a degree in robotics or programming to get started. Anyone on any shop floor can program and maintain a robot with READY’s Forge/OS.

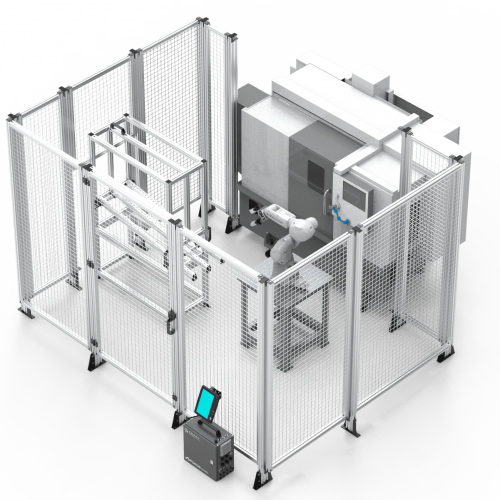

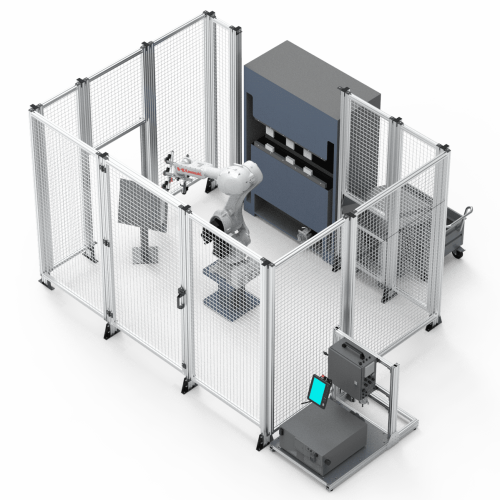

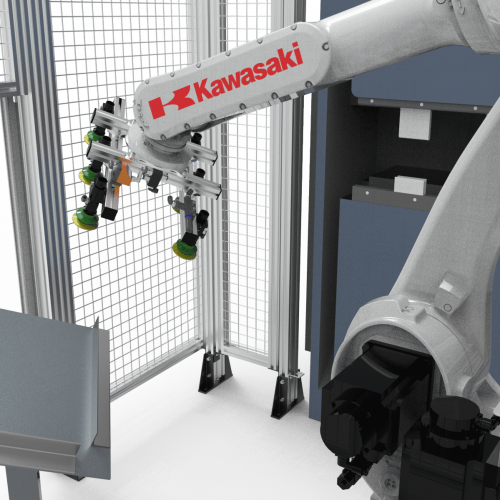

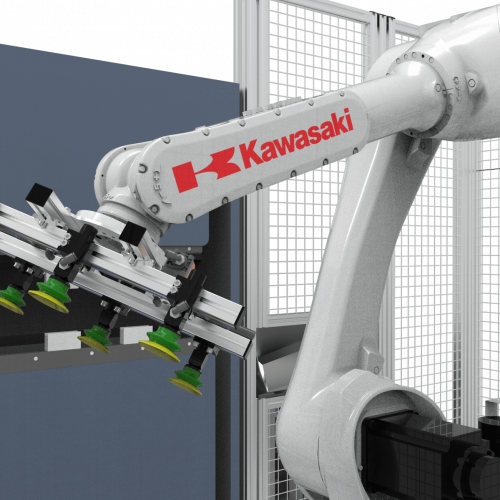

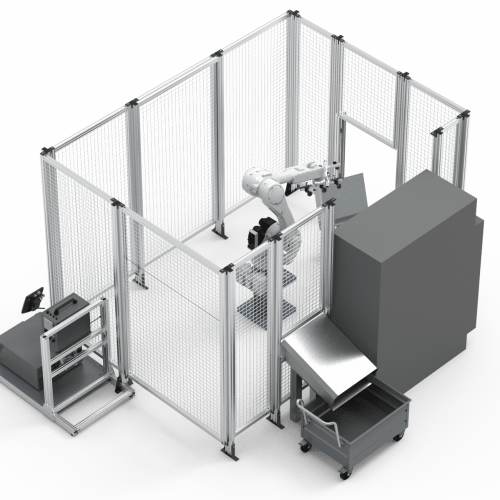

Press Brake Machine Tending

Implement robotic press brake tending with a 6-axis robot for lights out production. It is also possible to use a Fanuc CRX10L cobot which is ideal for small sheets and parts. Utilizing a cobot can eliminate the requirement for fencing and guarding.

Increase efficiency while reducing per-part costs with an automated workcell. An robotic press brake tending cell powered by READY’s Forge/OS is ideal for high mix, low volume shops looking to squeeze out as much efficiency as possible. Our no-code programming software, Task Canvas, will ensure that your existing machine operators will be able to program and maintain a robotic press brake tending cell with very little training.

Contact us to learn more about how we can help you implement robotics at your facility.

Schedule Time To See How It Works

We’re coming to your town!

Contact us today to reserve your time.

We’ll review your current operations, offer suggestions on improvements, and discuss the right mix of automation to help you achieve higher efficiencies.